Rickenbacker Guitar Factory Tour - Part 1/3- 09.18.09

As promised in the last post showing you the Beatles Rock Band controller versus the actual Rickenbacker 325~ here’s a peek into how Rickenbacker guitars are actually made! I had so many pictures because their whole process is so fascinating that instead of cutting TOO many of them, i’m making this a three parter… so first, come take a peek into the woodshop on the next page! Stunning how these beautiful pieces of wood get transformed into the guitars we know and love…

As promised in the last post showing you the Beatles Rock Band controller versus the actual Rickenbacker 325~ here’s a peek into how Rickenbacker guitars are actually made! I had so many pictures because their whole process is so fascinating that instead of cutting TOO many of them, i’m making this a three parter… so first, come take a peek into the woodshop on the next page! Stunning how these beautiful pieces of wood get transformed into the guitars we know and love…

Rickenbacker woodshop: Model 4001c64 bass neck headstock ears being

glued

Bass headstock shaped on CNC machine

alternate view

Pearlescent inlays are glued by hand in the fretboards.

The back of the neck is uniformally sanded after the fretboards are

attached

Bass bodies shaped on the CNC machine

Rickenbacker’s glue room

Body binding is masterfully glued on by hand

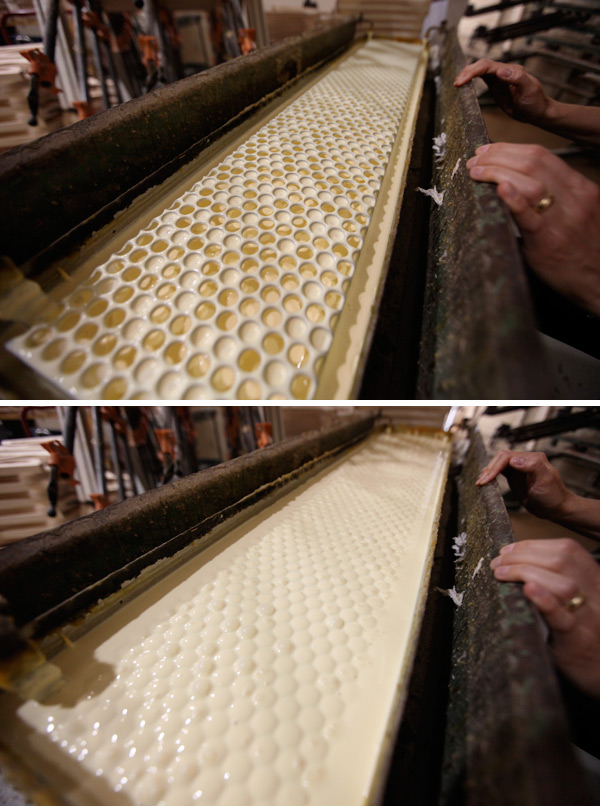

Vat of glue—the “behive” holes ensure uniform application of glue in the

neck-to-body joint

Woodshop: Model 381v69 guitar body phenolic spoilboard—Quick demo of

toolpath process on the CNC machines

Gasket/vacuum channel detail of 381 body spoilboard

330 body interior after being routed out on the CNC machines

The Rickenbacker Factory Series:

1. The Beatles Rock Band controller versus the actual Rickenbacker 325

2. peek into the woodshop

3. Painting and electronic components and finishing

4. A look at the museum - incredible design details from vintage pieces, limited editions, and concepts that never made it to market…

So cool! Too bad they don’t offer a factory tour like PRS, Carvin, Martin, Taylor and Gibson! Seeing how they achieve those curves in the wood would be AMAZING! Come on John! Let us in for a peak!!

----- Jake 04.02.13 19:12